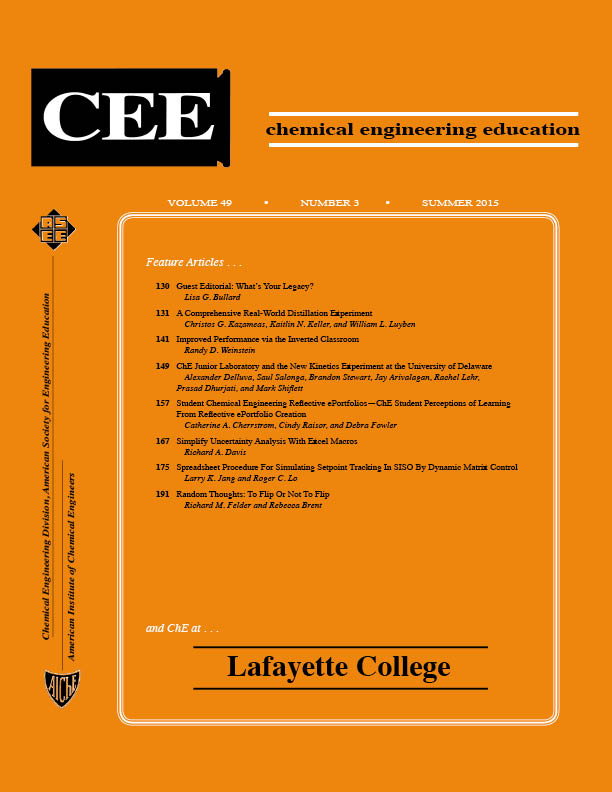

A Comprehensive Real-World Distillation Experiment

Abstract

Most undergraduate mass-transfer and separation courses cover the design of distillation columns, and many undergraduate laboratories have distillation experiments. In many cases, the treatment is restricted to simple column configurations and simplifying assumptions are made so as to convey only the basic concepts.

In industry, the analysis of a real operating distillation column is a very important issue in terms of improving performance (maximizing capacity, minimizing energy consumption, etc.). Few of the simplifying assumptions apply, and a rigorous analysis is required to achieve accurate results.

This paper discusses a distillation experiment that brings out many important practical aspects of using operating data from a typically complex distillation process to assess performance. The complexities include an economizer (feed preheated by overhead vapor), non-optimum feed tray location, inefficient trays, subcooled reflux and subcooled feed. Experimental results are compared to the predictions of computer simulations. Both total reflux operation and normal operation with feed and product streams are explored. One of the most important concepts derived from the experiment is how to startup the process.